Frenger® supplies new Children's Assessment Unit at Barnsley Hospital

Adding to Frenger's already extensive healthcare portfolio, the new Children's Assessment Unit at Barnsley Hospital was supplied with their range of Eco™ Healthcare Chilled Beams and their Modula ceiling recessed SP (Standard Performance) and HP (High Performance) Radiant Heating Panels.

The new assessment unit is part of a wider £3 million (GBP) investment into the children's services at Barnsley Hospital, with a new children's Emergency department also part of this recent investment.

The state-of-the-art unit, which was delivered during the COVID-19 pandemic, provides young patients who are requiring urgent help and assessments with year round care, with the ward being open 24 hours a day, 7 days a week.

Previously the assessment unit and the children's emergency department at Barnsley Hospital was in separate departments on the site, therefore the move into one collective location will allow paediatric specialists to work closer for "improved communication and logistics" providing better care for the young patients of Barnsley.

The decorated units inside the facility, which is part of a wider extension of the hospitals core emergency department, have been added to comfort young patients, enhance the play areas, with TV screens being looped with "specially designed animated videos to help make young patients more at ease and understand more about common procedures".

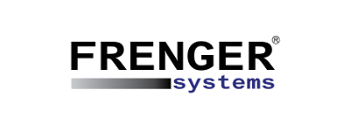

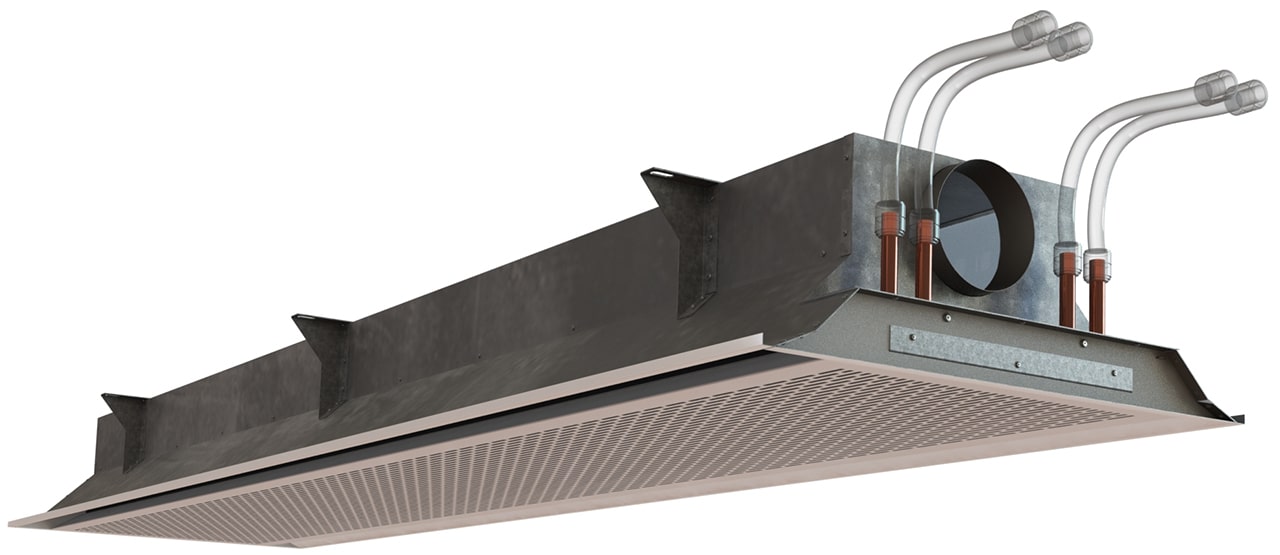

Eco™ Healthcare Chilled Beams

Frenger® supplied the new Children's assessment unit with their range of Eco™ Healthcare Chilled Beams which are specifically designed for healthcare applications. The Chilled Beam itself comes with a closed case/back design, so the filtered fresh air and the local recirculated air distributed does not come into contact with any 'dirty' ceiling void air and does not use any extracted air. This ensures that cross contamination does not occur and Frenger's Eco Healthcare Active Chilled Beams provide cleaner air (Indoor Air Quality) than other HVAC ventilation systems currently on the market.

Frenger's Chilled Beams are also designed to contribute low air movement to the occupied space, which therefore reduces the risk of spreading airborne pathogens, due to Chilled Beams not taking indoor air from one room and distributing it to adjacent rooms.

The Eco™ Healthcare Beams are supplied as standard with various key healthcare features including a 'drop down' heat exchanger that can be inspected and cleaned from within the room (no need to access the ceiling void), with all 4 sides of the heat exchanger being fully accessible for easy periodic cleaning and low maintenance.

The conditioned air from the beam is evenly distributed along the length of the unit for optimised heat exchange, energy efficiency, and so the air is uniformly spread throughout the occupied space in a controlled and consistent manner thanks to Frenger's AMDV (Air Management Discharge Vanes) and Coanda effect to entrain the conditioned air against the ceiling to ensure optimal thermal comfort levels and indoor air quality (IAQ).

Thermal comfort and indoor air quality (IAQ) is particularly important for healthcare applications and these Eco Healthcare Active Chilled Beams provide the optimum in meeting the criteria. Also given the low noise from Eco Healthcare this is also good for patient Wellbeing as studies show high ambient noise levels in patient rooms is believed to have negative impacts upon patients and their health and wellbeing. The impacts of other noisy HVAC systems can range from a lack of sleep, to elevated blood pressure, or extended recovery times. Thankfully Eco™ Healthcare Chilled Beams provides low noise levels, and also provides good Thermal Comfort; excellent energy efficiency and low maintenance.

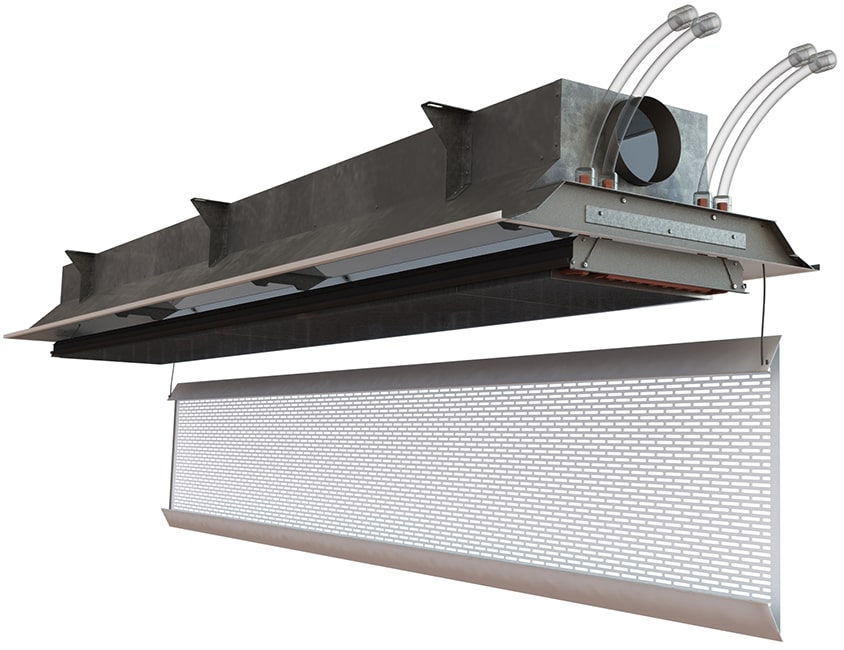

SP & HP Modula Radiant Heating Panels

Frenger® also provided the new assessment unit with their SP (Standard Performance) and HP (High Performance) Modula Radiant Heating Panels which were recessed into the ceiling grid/plasterboard to provide an unobtrusive heating solution.

Modula has been specifically designed and developed for use in schools and healthcare environments, where a smooth faced simple-to-install panel with a high heating capacity is the preferred solution. The panel also has long product life if maintained correctly (in excess of 25 years) as it has no moving parts and can be fully recycled at the end of its product life.

The panel is constructed from smooth-faced Zintec with extruded aluminium heat exchanger pipes seats which are fully bonded. The Copper heat coils are inserted into the pipe seats for excellent heat transfer characteristics. The 15mm copper coils are produced in-house on Frenger's full CNC Serpentine Bend Machine from thousand metre drums of copper to make the heating coils without any joints whatsoever and to safeguard against the risks of leakage.

All panels are insulated with class 'O' foil 'wrapped' mineral wool insulation pads of 45kg/m³ density. The technology employed in the construction of Frenger's Radiant Heating Panels result in a very high heating capacity, all of which are designed, developed, and tested in Frenger's Climatic Test Laboratories and are also Independently Tested and Certified to EN13047.

You can learn more about the products Frenger® has to offer by visiting their products page or read more articles about the international projects Frenger® has supplied on their latest news page. Alternatively, you can contact their office on 61 2 9006 1147 or sales@frenger.com.au.