In-House Technical Capabilities

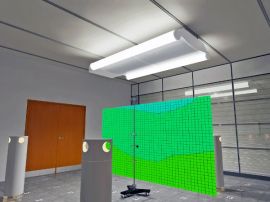

Frenger Systems® have 3 number state-of-the-art Climatic Testing Laboratories at their technical facility situated at the prestigious Pride Park, Derby, UK. Each Laboratory has internal dimensions of 6.3 x 5.7 x 3.2m high and includes a thermal wall so that both internal and perimeter zones can be tested. The test facilities are fixed in overall size and construction and can facilitate both Steady and Non-Steady State Testing.

Project specific testing can be simulated accurately by adjusting the finished floor level (FFL) to the underside of the ceiling by either introducing a suspended ceiling or adjusting the raised floor height.

Project Specific Testing

Project specific mock-up testing is a valuable tool which allows the Client to fully assess the proposed system and determine the resulting indoor quality and comfort conditions; the physical modelling is achieved by installing a full scale representation of a building zone complete with internal & external heat gains (Lighting, Small Power, Occupancy & Solar Gains).

Most Project Specific tests are to validate compliance to BS EN ISO 7730 for Thermal Comfort and for product performance in terms of output (Note: All of Frenger's chilled beam products have been independently tested and certified by Eurovent for performance in terms of output, but Eurovent does not test for Thermal Comfort, hence Frenger's in-house Climatic Test Laboratories. Frenger® factory certification number 13.10.005.).

The installed mock-up enables the client to verify the following:

- Product performance under project specific conditions

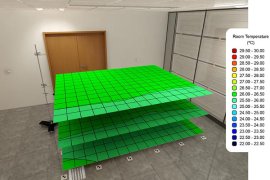

- Spatial air temperature distribution

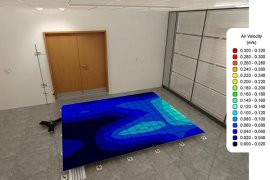

- Spatial air velocities

- Experience thermal comfort

- Project specific aesthetics

- Experience lighting levels (where relevant)

- Investigate the specific design and allow the system to be enhanced

The project-specific installation and test is normally conducted to verify:

- Product capacity under design conditions

- Comfort levels - air temperature distribution

- Comfort levels - thermal stratification

- Comfort levels - draft risk

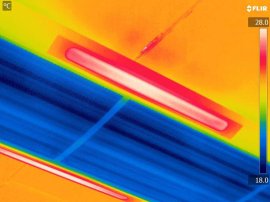

- Comfort levels - radiant temperature analysis

- Smoke test video illustrating air movement

Frenger® also employ the use of cutting-edge thermography technology with FLIR® thermal imaging cameras to help determine the best way to improve project specific installations, as well as to further the development of Frenger's spatial conditioning technology.

Also situated in-house at Frenger's UK technical facility are 2 number Photometric Testing Laboratories as well as an in-house Acoustic Laboratory. To find out more information about these facilities, click one of the buttons below.