Increase in Performance for Frenger's Heating Panels

Recent independent testing performed by HLK (Heizung Lüftung Klimatechnik) Stuttgart, has shown that the heating performance of Frenger’s Modula SP Radiant Heating Panels has increased by more than 10%.

This increase in performance is mainly due to new bonding techniques employed during the in-house production of the radiant heating panels. Frenger’s heating capacity of their CE certified Modula SP panels has increased from 476 W/m² @ 55∆TK to 527 W/m² @ 55∆TK based on the independent testing conducted in accordance with EN 14037. These results correspond with Frenger’s own testing carried out at Frenger’s BSRIA calibrated in-house climatic test facility in Derby, UK.

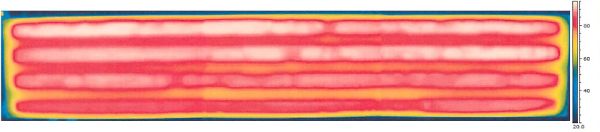

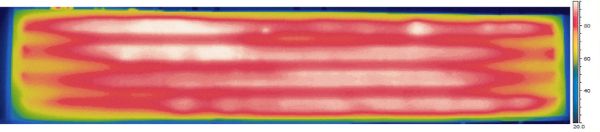

Frenger’s new bonding technique has been refined over several years of research and development utilising the latest in thermal imaging technology to analyse the optimal bonding methods.

New Bonding Technique

Old Bonding Technique

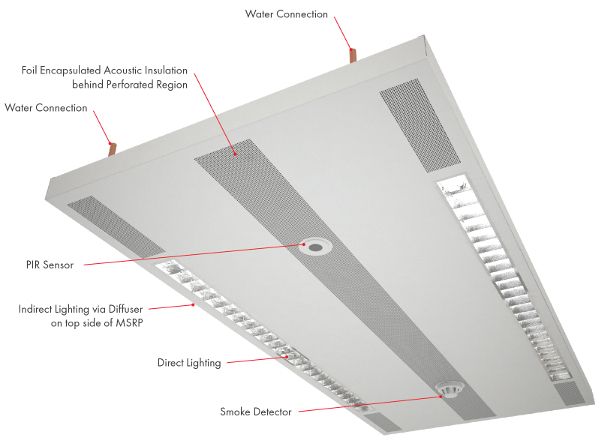

Modula Radiant Heating Panel

Modula is an unobtrusive radiant heating panel compatible with all types of exposed ceiling grid systems as standard. The panels are manufactured from 1mm thick smooth-faced zinc coated steel and are powder coat finished in RAL9010 (White) as standard, although other RAL colours are available as an optional extra. Modula panels incorporate a seamless serpentine copper coil formed on a full CNC state-of-the-art in-house bend machine that decoils one thousand metre drums of copper to form individual coils with up to 72 linear metres of pipe without any joints whatsoever (thus eliminating any risk of leakage). These bespoke coils (70, 100 and 150mm tube centres) are pressure inserted into extruded aluminium pipe seats to give high metal-to-metal contact and the pipe seats are then securely bonded to the rear of the steel panels. This arrangement delivers excellent heat transfer characteristics. Panels are insulated with 45 Kg/m³ density 25mm thick class ‘O’ foil encapsulated mineral wool insulation. The technology employed in the construction of the Modula panel results in very high heating capacity at low water mass flow rates.

Modula has been specifically developed for use in schools and healthcare environments, where a smooth faced simple-to install panel with high heating capacity is the preferred solution. Anti-bacterial coatings are also available as an option.

Multi-Service Radiant Panels

Using a combination of the Modula Radiant Panel and Multi Service Chilled Beam (MSCB) technology, Frenger’s Acoustic, Lighting and Heating Rafts, otherwise known as Multi Service Radiant Panels (MSRP’s) are a free hanging radiant heating panel which may also have options of lighting and/or acoustic sound absorbing properties.

An ideal solution for schools, youth centres and universities, other services can also be incorporated such as apertures for sprinkler heads, compartment trunking for other electrical services, apertures for PA and VA speakers plus lighting control, PIR, Photocells and other building services which are 100% pre-fabricated off-site in a controlled factory environment.

Virtually any type of lighting solutions such as direct only, indirect only, combination of direct/indirect either from the same or different source can be accommodated and are designed, manufactured and safety tested in house. The performance testing of Heating, Lighting and Acoustic solutions are also carried out in Frenger’s in house Climatic, Photometric and Acoustic Laboratories and Frenger also make use of third party acoustic testing for independent verifications and accreditations.

Design Options

The following building services can be integrated within Frenger MSRP's:- Heating

- Acoustic Insulation

- Control Valves

- Lighting Sensors

- Direct LED Lighting

- Sprinklers

- Smoke Detectors

- PA / VA Speakers

- LED Up-lighting

- Emergency LED Lighting

- Electrical Compartmentation

- Distribution Water Pipes

Extruded Polycarbonate LED Lighting

Micro Prismatic LED Lighting

Aluminium Louvre LED Lighting