Frengerwarm LTHW Radiant Panels are a system of custom made, smooth faced aluminium or steel panels manufactured to any length and any width to suit the exact application to give a more tailored solution.

Frengerwarm has been specifically developed for use in schools, sports halls, offices and healthcare environments, where a smooth faced panel with high heating capacity is the preferred solution. Frengerwarm is tested in accordance with the new harmonised European Standard EN 14037.

Frengerwarm Radiant Panels can be supplied for wall mounting, free-hanging, surface mounted, or recessing into a suspended ceiling system. Bespoke systems can be designed for specific application requirements, please contact Frenger for further assistance with selecting the correct product for your project.

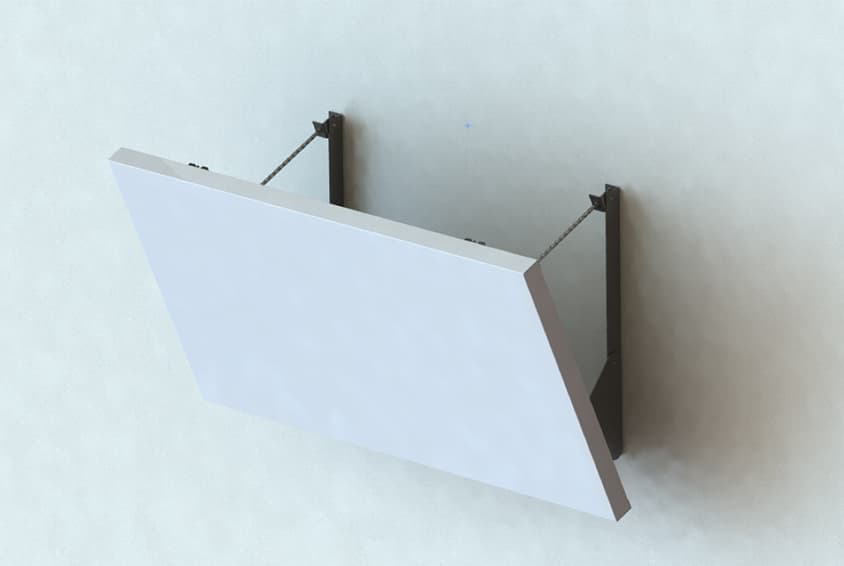

Wall mounting the Radiant Panels is a good option if the ceiling space is lacking space due to other building services such as wind catchers, luminaires, sports equipment etc. The panel can be mounted at high level on the wall which frees up space on the walls at low level.

The image above shows the Frengerwarm Radiant Heating Panel wall mounted at an angle.

The image above shows the Frengerwarm Radiant Heating Panel surfaced mounted.

The image above shows the Frengerwarm Radiant Heating Panel ceiling recessed inside the Nottingham Trent University Engineering Building project.

Panel sections can be supplied in any bespoke lengths up to 3m and any bespoke widths between 0.3m-1.0m. Panel runs longer than 3m can be made up of multiple panel sections and infill sections can also be supplied if required to make continuous runs up to 50m long.

Copper pipes are expanded under pressure into extruded aluminium pipe seats to give high metal-to-metal contact and the pipe seats are bonded to the rear of the steel panels. All serpentine copper coils are produced in-house by Frenger on its full CNC state-of-the-art serpentine bend machine from thousand metre drums of copper to avoid any joints in the heating coil. This arrangement delivers excellent heat transfer characteristics, providing no risk of leaks whatsoever.

Standard Features

- Tested to EN 14037

- Custom product to suit your project requirements

- Smooth flat faced unobtrusive design

- Steel Panel - Up to 588 W/m2 @ 55.5 dtK room (mwt - room temp)

- Aluminium Panel - Up to 630 W/m2 @ 55.5 dtK room (mwt - room temp)

- Standard powder coat finish RAL 9010 (White) 25% gloss (±5%) or Pre-Coat finish equivalent to RAL 9016 (White) 20% gloss (±5%)

Optional Features

- Can be customised to suit your specific project needs

- Can be supplied in any standard RAL powder coat finish

- Aluminium or Steel panels

- Infill/Dummy panel sections

- Any other features required, please contact Frenger

water connections: 15mm OD EN1057:R250 Copper

Connection Possibilities

All of our copper heating coils are manufactured in-house using our state of the art CNC Serpentine Bend Machine from thousand-metre drums of copper to make the sinusoidal copper coils with no joints whatsoever and as such provides no risk of leaking.

Copper Heating Coil: 15mm OD EN12449 / EN12735-2

Connection: Horizontal or Vertical, same end or opposite.

Maintenance

The unit has no moving parts, and therefore maintenance requirement is limited to periodic cleaning of the surface of the panel.

Installation

Multiple fixing methods are available, please contact Frenger for further details.

For simplicity and flexibility, we recommend that flexible stainless steel braided EPDM hoses are used to connect the Frengerwarm panel pipe work connections to your mains pipework connections.

REVIT models are available on request.

Frengerwarm Projects

If you require any further information, or have a project to discuss, please contact us on 61 2 9006 1147 or sales@frenger.com.au as our technical team are here to assist.